Amazon KDP Print on Demand Manufacturing, Shipping, Margins

- by Billie Lucas

Amazon KDP Print on Demand: How Manufacturing, Shipping, and Margins Work

Estimated reading time: 5 minutes

- Amazon KDP Print on Demand removes upfront inventory costs but creates variable per-unit expenses that affect royalties.

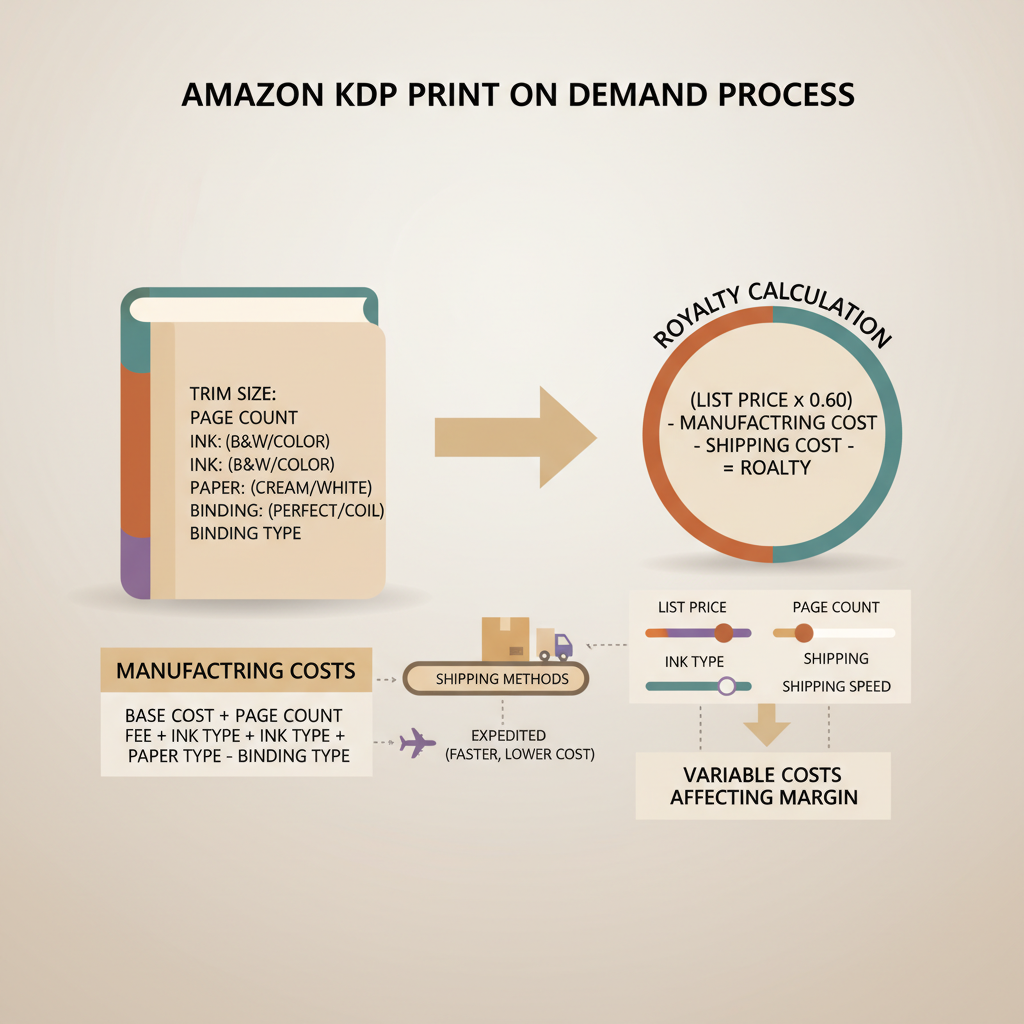

- Trim size, page count, ink, paper, and binding drive print cost and therefore your margin.

- Shipping method, distribution choices, and author-copy strategy change delivery speed and net profit.

- Tools that handle covers and EPUBs reduce formatting errors and speed publication.

What Amazon KDP print on demand actually is

Amazon KDP print on demand lets you sell paperbacks and hardcovers without pre-printing inventory. Instead of ordering pallets and storing boxes, KDP prints a copy only after a customer buys it and ships that single copy directly to them.

For authors this removes upfront print runs and storage costs, but it also creates variable per-unit costs that affect profit margins. Using KDP Print is ideal when you want low overhead, fast setup, and seamless Amazon integration—especially if your main market is Amazon shoppers. If you need a quick primer on fees and how they affect royalties, see the Amazon Kdp Fees Breakdown for a clear look at how costs translate to profit.

Manufacturing and print quality: how KDP prints your book

How a POD book is made

When an order arrives, KDP assembles your interior PDF or ebook file, matches it to the chosen trim size, paper type, and binding, and routes it to the nearest printing facility. The press prints the interior, binds the pages, applies the cover, and ships the finished book to the buyer.

This process usually completes within 24–72 hours for production, but transit time depends on destination and logistics choices.

Key manufacturing variables that change cost and quality

- Trim size: Common sizes (6″ x 9″, 5.5″ x 8.5″) are cheapest; unusual sizes increase per-unit cost.

- Page count: POD pricing is usually a base fee plus a per-page charge—longer books cost more.

- Ink choice: Black-and-white interiors are significantly cheaper than color; full color multiplies printing cost.

- Paper weight and finish: Standard cream or white stock is cheapest; premium paper increases cost and shipping weight.

- Binding and cover: Paperback (perfect binding) is standard; hardcovers and specialty finishes may be more limited and costly.

Why print quality can vary

KDP uses regional print facilities that may employ different presses and toner settings. That can cause slight shifts in contrast, color saturation, and spine alignment between runs or locations. For most text-heavy nonfiction these variations are minor, but photo-heavy or color-intensive books will show more noticeable differences compared with an offset press.

When to choose higher-quality options (and when not to)

Choose standard B&W on cream or white for text-centric nonfiction to balance cost and readability. Reserve color and premium paper for content that depends on visuals—children’s books, cookbooks, or photo essays.

If brick-and-mortar stores or distributors require higher fidelity, a hybrid approach often works: use KDP for Amazon sales and a service like IngramSpark for bookstore distribution and premium printing.

Shipping, distribution, and why margins vary

How Amazon’s royalty math works for print

For each print sale on Amazon, royalties are calculated by subtracting the print cost from the list price, and then applying the royalty rate. For paperbacks sold on Amazon this is typically 60% of the list price after print cost is deducted. Higher print costs—color, heavy paper, long page counts—directly shrink your royalty.

Factors that change margins

- List price: Too low and you lose margin; too high and discoverability suffers.

- Distribution channel: Amazon sales usually give better royalties for KDP Print; expanded distribution can reduce percentage due to extra fees.

- Returns and discounts: Retailer allowances and discounts affect net revenue when selling beyond Amazon.

- Shipping destination and method: Domestic prints route from nearby plants; international shipping or distant printing increases time and cost.

- Author copies: You buy these at print cost plus shipping—factor in shipping and import/export if ordering across borders.

Why delivery times change

Regional plants manage capacity and seasonal workload. During peak periods some facilities slow down. Author copies typically take longer than customer orders because they use different logistics channels. Tight file prep and avoiding last-minute format changes helps keep production in faster facilities.

Practical steps authors can take to improve margins

- Optimize interiors: remove unused large images, trim pages, and use black-and-white unless color is required.

- Pick standard trim sizes and paper types to leverage lower price tiers.

- Set prices strategically by knowing your break-even print cost and desired royalty.

- Use distribution selectively: KDP for Amazon-first, and a second partner for bookstores if needed.

- Order author copies conservatively; consider traditional short runs only when large quantities and storage are viable.

How production choices affect reader perception

Readers judge nonfiction by clarity and professionalism. A crisp cover, readable typography, and solid paper quality matter. Don’t cut specs so far that the reader experience suffers.

Invest in a professional cover and clean ebook formatting—covers that perform at thumbnail size and well-structured EPUBs improve sales and reduce returns. When you need a cover designed to sell, use the Cover Generator to produce front covers with clear typography and genre-appropriate visuals.

When you’re ready to convert your finished file into a store-ready EPUB, the EPUB converter automates metadata, cover embedding, and navigation so previews behave correctly on Kindle, Kobo, and Apple Books.

If you are preparing both paperback and ebook files, Bookautoai tools simplify creating those formats together and reduce formatting errors when uploading to retailers.

Practical case studies (short examples)

- Low-cost trade paperback: 6″ x 9″, 180 pages, B&W on cream paper—low print cost and strong royalty for Amazon sales.

- Visual guidebook: 8.5″ x 11″, 120 pages, full color—high print cost and lower royalty per sale but justified when visuals drive value.

- Long technical manual: 350+ pages—higher per-page cost and heavier shipping; consider splitting into volumes or offering a detailed ebook.

Making the right choice for your goals

If your goal is to maximize Amazon sales with minimal setup, KDP Print is usually the right choice. If you need global bookstore placement, higher color fidelity, or specific trim sizes, supplement KDP with a service that reaches bookstores and libraries. Many authors use a mixed approach: KDP for Amazon and another print partner for non-Amazon channels.

For upload and distribution tools related to KDP and other retailers, consider services that specialize in publisher uploads to reduce manual errors when you publish.

Final thoughts

Understanding how manufacturing, shipping, and distribution influence margins turns pricing and production decisions from guesswork into predictable choices. Combine clear production specs with strong cover design and error-free ebook conversion to keep costs down and reader satisfaction high.

Write like a Human, Publish like an author.

Visit Bookautoai and try our Demo book.

FAQ

Is Amazon KDP print on demand cheaper than ordering a short run from a local printer?

It depends. KDP removes upfront print and storage costs and is lower risk for uncertain sales. Local offset runs can have lower per-unit cost at larger quantities but require storage and handling.

How quickly will author copies arrive?

Author copies often take longer than customer orders—expect around 9–11 days in many cases. Customer orders routed through nearby facilities can arrive faster.

Can I get hardcover copies through KDP Print?

KDP offers hardcover options in many markets, but availability and pricing vary. For specialty finishes, a separate print partner may be required.

Will my paperback look the same every time it’s printed?

Minor variations in color density, binding alignment, and cover wrap can occur between facilities and runs. For perfect consistency consider an offset run with a single large batch.

How do I avoid formatting errors that increase production time?

Use tools that prepare files correctly—proper margins, embedded fonts, correctly sized covers, and clean chapter structure. Automation tools and upload specialists can reduce errors when publishing to retailers.

Sources

- https://reedsy.com/blog/best-book-printing-services/

- https://self-publishingschool.com/print-on-demand-books/

- https://selfpublishingwithdale.com/index.php/2025/02/13/kdp-print-vs-ingramspark-comparison/

- https://www.bookdesignmadesimple.com/self-publishing-services-compared/

- https://kdp.lulu.com

- https://mandilynn.com/2022/06/14/the-best-print-on-demand-company-comparing-book-publishing-with-amazon-kdp-ingramspark-beyond/

- https://www.launchmybook.com/the-most-popular-self-publishing-platforms-pros-cons/

Amazon KDP Print on Demand: How Manufacturing, Shipping, and Margins Work Estimated reading time: 5 minutes Amazon KDP Print on Demand removes upfront inventory costs but creates variable per-unit expenses that affect royalties. Trim size, page count, ink, paper, and binding drive print cost and therefore your margin. Shipping method, distribution choices, and author-copy strategy…